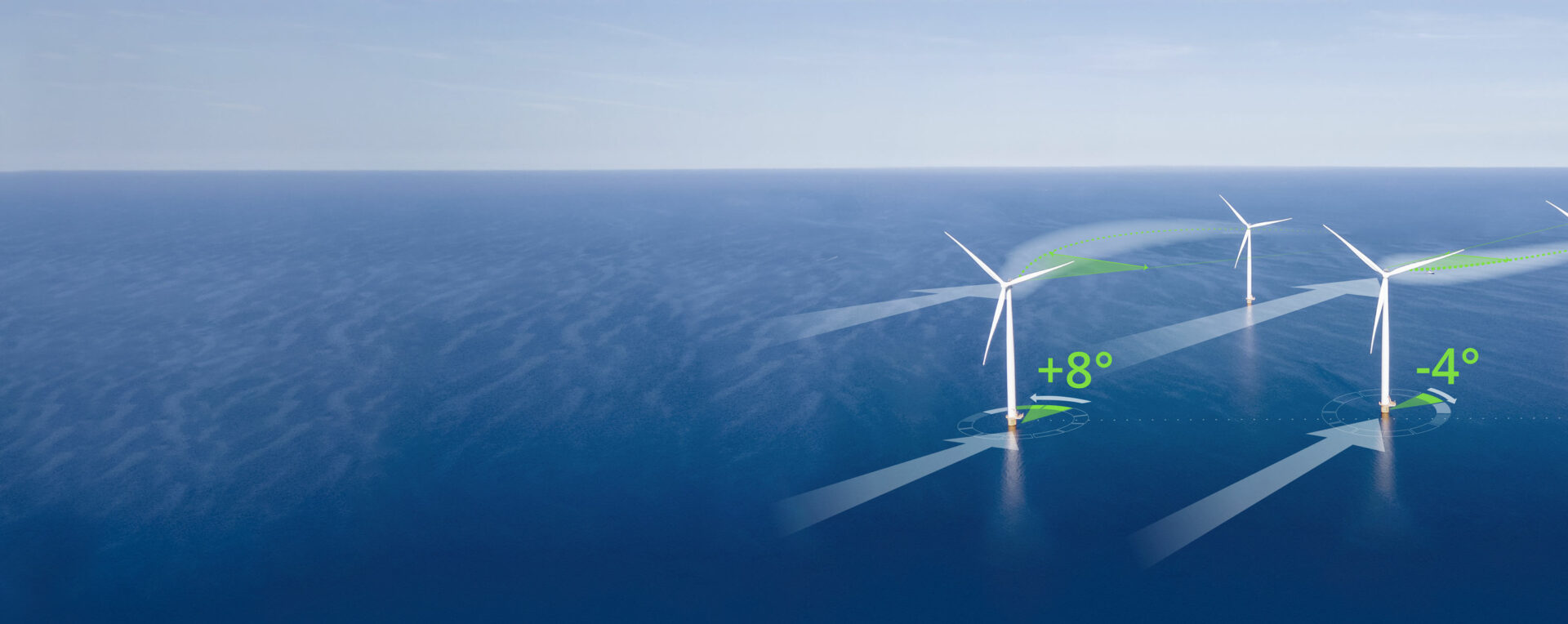

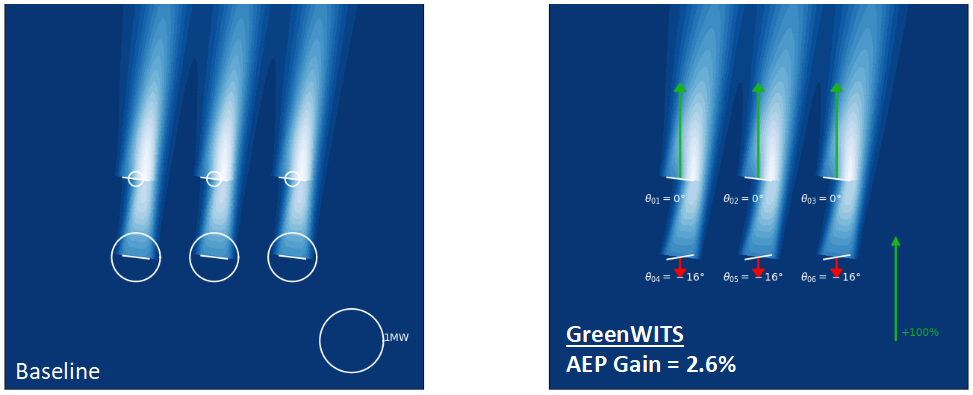

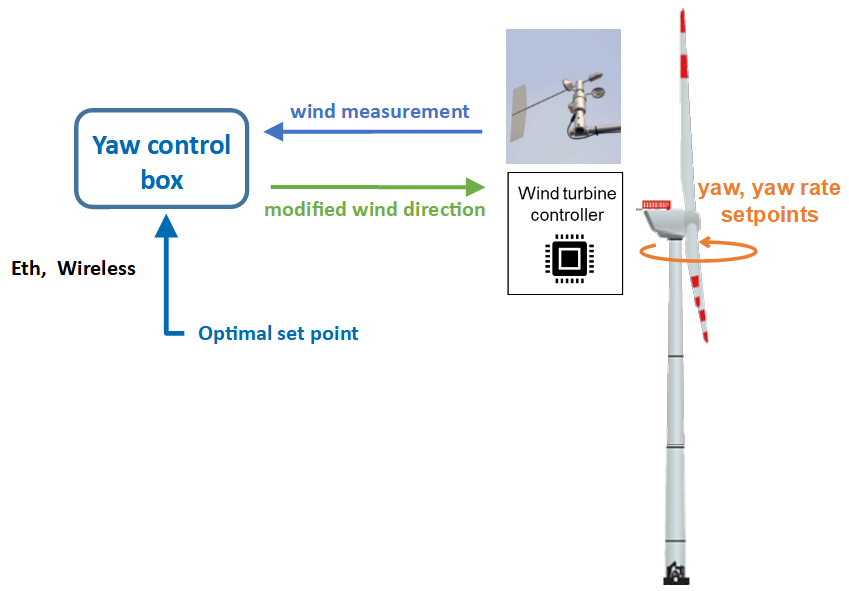

Traditionally, wind turbines have been individually controlled to face the incoming wind, aiming to maximize their individual power production. However, this strategy is often suboptimal for overall wind farm performance. Wake steering control is a way to mitigate wake effects and optimize production at the wind farm level. It involves intentionally misaligning some or all wind turbines from the incoming wind direction to deflect their wakes, leading to an overall increase in energy production. Developing an effective wake steering control strategy is complex, and requires a deep understanding of wake physics and structural health aspects.