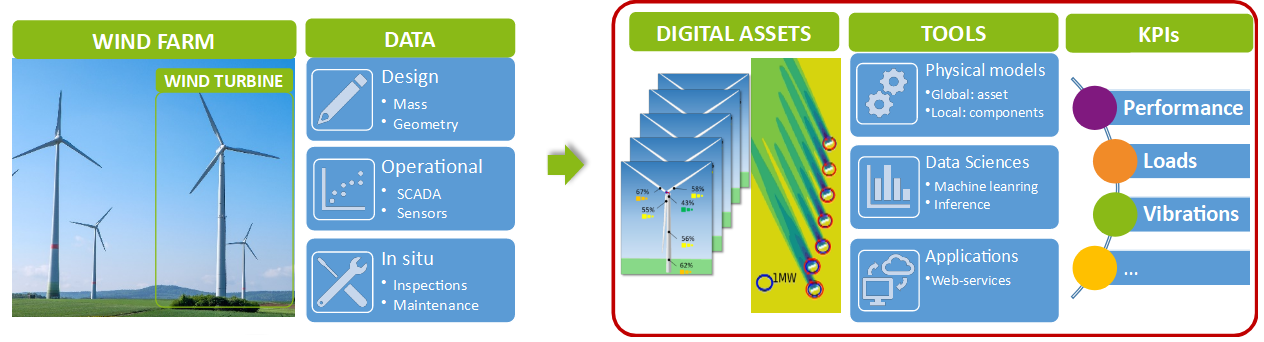

GreenWITS understands that optimizing the performance and health of wind assets is crucial for the profitability of wind farm owners. These factors directly impact operational efficiency and ultimately determine the success of wind energy projects. While a wealth of data is available from Wind Turbine Generator (WTG) SCADA and monitoring systems, identifying phenomena, and differentiating their origins remains a challenge.

Traditional health monitoring approaches involve the installation of sensors at critical locations on the structure to measure strains and vibrations under constant supervision. However, these methods can be costly and may lack long-term durability, making it difficult to comprehensively monitor all assets within a wind farm. This limitation results in increased inspection expenses and heightened risks of unexpected downtime and maintenance costs.